Introduction

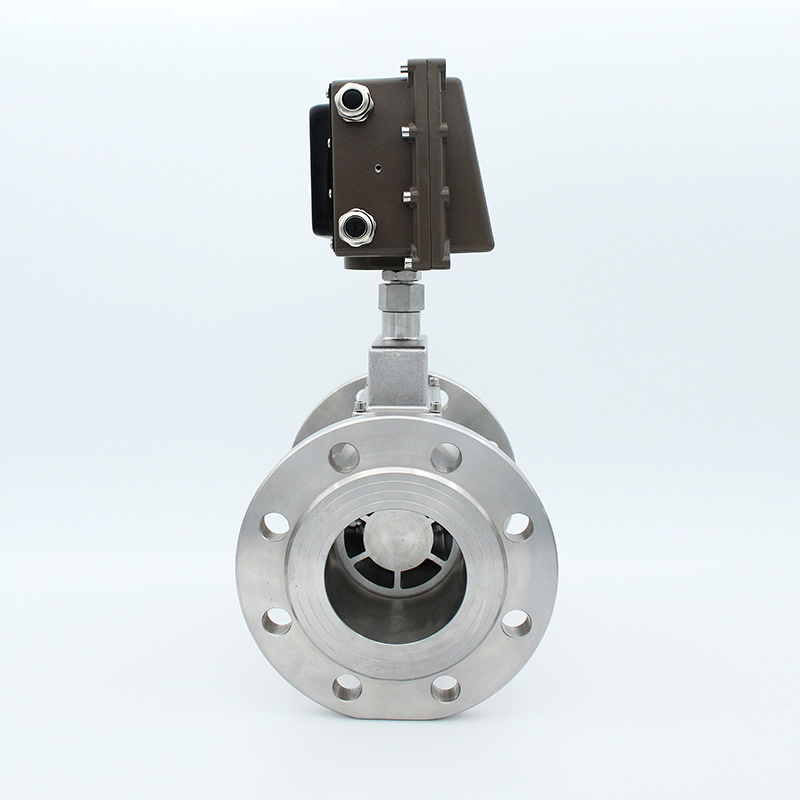

Electromagnetic flow meter is one of the most popular flow meters. Flange type electromagnetic flow meter has been used for more than 50 years worldwide. It is widely used for all conductive liquids in every industry, such as water, acid, alkali, milk, slurry etc.

Advantages

Electromagnetic Flow Meter Advantages and Disadvantages

The main advantages of using electromagnetic flow meter is that it is with no moving parts, no pressure loss and require very less maintenance.

Flange type magnetic flow meter can be made large size range from DN3-DN3000mm and with bi-directional flow measurement.

Compared with other liquid type flow meter, the limitations of magnetic flow meter is that it can only be used for conductive liquid.Regarding non or low conductive liquid such as petroleum products, organic solvents can not be used. Electromagnetic flow meter will be affected if there’s strong magnetic filed in the surrounding environment.

Application

Flange Electromagnetic Flow Meter Installation Requirement

Electromagnetic flow meter is widely used in water treatment, food industry, pharmaceutical, petrochemical, paper mill, chemical monitoring etc.

In the metallurgical industry, it is often used to control the flow of cooling water for continuous steel casting, continuous steel rolling, and steel-making electric furnaces;

In the field of water supply and drainage in public utilities, electromagnetic flow meters are often used for the transfer measurement of finished product water and raw water in water plants;

In the pulp process of the paper industry, electromagnetic flow meters are involved in the measurement of the flow of grinding pulp, water, acid, and alkali;

In the coal industry, measuring coal washing and pipeline hydraulic conveying coal slurry.

For food and beverage industries, it is used for beer and beverage filling measurement.

For chemical and petrochemical industries, it is used to measure corrosive liquids, such as acids and alkalis etc.

Table 1: Flange Magnetic Flow Meter Main Performances Parameters

| Model | QTLD-80-2-1-4-1-1-G-A-D16-2-A | |

| Size | DN80 | |

| Accuracy | ±0.5%FS | |

| Velocity | 0.1~15 m/s | |

| Repeatability | ≤0.17% | |

| Structure | Compact / remote, cable length 10m standard, 100m max | |

| Conductivity | > 5 μS/cm, demineralized water > 20 µS/cm | |

| Protection class | IP 68 | |

| Electrode | SUS316L | |

| Power Supply | 85~250 VAC (50/60 Hz), 20~36 VDC | |

| Power Consumption | <20W | |

Signal Output | Analog | 4~20mA ( load resistor 0~750Ω) |

| Pulse | Pulse | |

| Frequency | Forward & reverse flow output with a frequency range of 1~5000Hz | |

| Alarm | Two isolated open collector transistor (OCT) outputs for alarm signals | |

| Communication | RS485 MODBUS RTU standard, HART, GPRS, PROFIBUS optional | |

| Display | LCD Display,128X128mm, three lines, 4 buttons | |

| Instantaneous flow, total flow, flow velocity | ||

| Ambient Temperature | -20°C~60°C | |

| Ambient Humidity | 5 – 100%RH (relative humidity) | |

| Fluid Temperature | Compact: -20°C~80°C, Remote: -20°C~120°C | |

| Liner Material | Neoprene (-10°C~80°C) | |

| Flange Standard | DIN, ANSI, JIS | |

| Function | High and low alarm, exciting alarm, empty pipe alarm, self-diagnosis | |

| Display Unit | L/s, L/m, L/h, m3/s, m3/m, m3/h, UKG, USG, gal/s, gal/m, gal/h, kg/s, kg/m, kg/h, t/s, t/m, t/h | |

| Language | English, Chinese, Italian, Portuguese, French, Spanish, Korean | |

Table 2: Flange Magnetic Flow Meter Electrode Material Selection

| Electrode Material | Applications & Properties |

| SUS316L | Applicable to industrial/municipal water, wastewater and low corrosive mediums. Widely used in petroleum, chemical industries. |

| Hastelloy B | Strong resistance to hydrochloric acids below the boiling point. Resist against oxidable acids, alkali and non-oxidable salts. For instance, vitriol, phosphate, hydrofluoric acids, and organic acids. |

| Hastelloy C | Exceptional resistance to strong solutions of oxidizing salts and acids. For example, Fe+++, Cu++, Nitric acids, mixed acids |

| Titanium | Titanium can withstand corrosive mediums such as seawater, chloride salt solutions, hypochlorite salts, oxidable acids(including fuming nitric acids), organic acids, and alkali. Not resistant to high purity reducing acids such as sulphuric acids, hydrochloric acids. |

| Tantalum | Highly resistant to corrosive mediums. Applicable to all chemical mediums except Hydrofluoric Acids, Oleum and Alkali. |

| Platinum-iridium | Applicable to all chemical mediums except for Ammonium salts and Fortis |

Table 3: Flange Magnetic Flow Meter Flow Range

| Size | Flow Range & Velocity Table | |||||||

| (mm) | 0.1m/s | 0.2m/s | 0.5m/s | 1m/s | 4m/s | 10m/s | 12m/s | 15m/s |

| 3 | 0.003 | 0.005 | 0.013 | 0.025 | 0.102 | 0.254 | 0.305 | 0.382 |

| 6 | 0.01 | 0.02 | 0.051 | 0.102 | 0.407 | 1.017 | 1.221 | 1.526 |

| 10 | 0.028 | 0.057 | 0.141 | 0.283 | 1.13 | 2.826 | 3.391 | 4.239 |

| 15 | 0.064 | 0.127 | 0.318 | 0.636 | 2.543 | 6.359 | 7.63 | 9.538 |

| 20 | 0.113 | 0.226 | 0.565 | 1.13 | 4.522 | 11.304 | 13.56 | 16.956 |

| 25 | 0.177 | 0.353 | 0.883 | 1.766 | 7.065 | 17.663 | 21.2 | 26.494 |

| 32 | 0.289 | 0.579 | 1.447 | 2.894 | 11.575 | 28.938 | 34.73 | 43.407 |

| 40 | 0.452 | 0.904 | 2.261 | 4.522 | 18.086 | 45.216 | 54.26 | 67.824 |

| 50 | 0.707 | 1.413 | 3.533 | 7.065 | 28.26 | 70.65 | 84.78 | 105.98 |

| 65 | 1.19 | 2.39 | 5.97 | 11.94 | 47.76 | 119.4 | 143.3 | 179.1 |

| 80 | 1.81 | 3.62 | 9.04 | 18.09 | 72.35 | 180.86 | 217 | 271.3 |

| 100 | 2.83 | 5.65 | 14.13 | 28.26 | 113.04 | 282.6 | 339.1 | 423.9 |

| 125 | 4.42 | 8.83 | 22.08 | 44.16 | 176.63 | 441.56 | 529.9 | 662.34 |

| 150 | 6.36 | 12.72 | 31.79 | 63.59 | 254.34 | 635.85 | 763 | 953.78 |

| 200 | 11.3 | 22.61 | 56.52 | 113.04 | 452.16 | 1130.4 | 1356 | 1696 |

| 250 | 17.66 | 35.33 | 88.31 | 176.53 | 706.5 | 1766.25 | 2120 | 2649 |

| 300 | 25.43 | 50.87 | 127.2 | 254.34 | 1017 | 2543.4 | 3052 | 3815 |

| 350 | 34.62 | 69.24 | 173.1 | 346.19 | 1385 | 3461.85 | 4154 | 5193 |

| 400 | 45 | 90 | 226.1 | 452 | 1809 | 4522 | 5426 | 6782 |

| 450 | 57 | 114 | 286.1 | 572 | 2289 | 5723 | 6867 | 8584 |

| 500 | 71 | 141 | 353.3 | 707 | 2826 | 7065 | 8478 | 10598 |

| 600 | 102 | 203 | 508.7 | 1017 | 4069 | 10174 | 12208 | 15260 |

| 700 | 138 | 277 | 692.4 | 1385 | 5539 | 13847 | 16617 | 20771 |

| 800 | 181 | 362 | 904.3 | 1809 | 7235 | 18086 | 21704 | 27130 |

| 900 | 229 | 458 | 1145 | 2289 | 9156 | 22891 | 27469 | 34336 |

| 1000 | 283 | 565 | 1413 | 2826 | 11304 | 28260 | 33912 | 42390 |

| 1200 | 407 | 814 | 2035 | 4069 | 16278 | 40694 | 48833 | 61042 |

| 1400 | 554 | 1108 | 2769 | 5539 | 22156 | 55390 | 66468 | 83084 |

| 1600 | 723 | 1447 | 3617 | 7235 | 28938 | 72346 | 86815 | 108518 |

| 1800 | 916 | 1831 | 4578 | 9156 | 36625 | 91562 | 109875 | 137344 |

| 2000 | 1130 | 2261 | 5652 | 11304 | 45216 | 113040 | 135648 | 169560 |

| 2200 | 1368 | 2736 | 6839 | 13678 | 54711 | 136778 | 164134 | 205168 |

| 2400 | 1628 | 3256 | 8139 | 16278 | 65111 | 162778 | 195333 | 244166 |

| 2600 | 1910 | 3821 | 9552 | 19104 | 76415 | 191038 | 229245 | 286556 |

| 2800 | 2216 | 4431 | 11078 | 22156 | 88623 | 221558 | 265870 | 332338 |

| 3000 | 2543 | 5087 | 12717 | 25434 | 101736 | 254340 | 305208 | 381510 |

| Remark:Suggest flow velocity range 0.5m/s – 15m/s | ||||||||

Table 4: Flange Magnetic Flow Meter Selection Guide

| QTLD | X | X | X | X | X | X | X | X | X | X | X | |

| Caliber size | DN3-DN3000 (1/8″-120″) | |||||||||||

Structure | Compact | 1 | ||||||||||

| Remote | 2 | |||||||||||

| Compact with explosion proof | 3 | |||||||||||

| Remote with explosion proof | 4 | |||||||||||

Accuracy | ±0.5% | 1 | ||||||||||

| ±0.2% | 2 | |||||||||||

| Others | 3 | |||||||||||

Lining Material | PTFE | 1 | ||||||||||

| FEP | 2 | |||||||||||

| PFA | 3 | |||||||||||

| Neoprene | 4 | |||||||||||

| Polyurethane | 5 | |||||||||||

| Hard Rubber | 6 | |||||||||||

| Ceramic | 7 | |||||||||||

| Others | 8 | |||||||||||

Electrode Material | SS316L | 1 | ||||||||||

| Hastelloy B | 2 | |||||||||||

| Hastelloy C | 3 | |||||||||||

| Titanium | 4 | |||||||||||

| Tantalum | 5 | |||||||||||

| Platinum-iridium | 6 | |||||||||||

| Stainless steel covered with tungsten carbide | 7 | |||||||||||

| Others | 8 | |||||||||||

Sensor Material | Carbon steel | 1 | ||||||||||

| SS304 | 2 | |||||||||||

| SS316 | 3 | |||||||||||

Power Supply | 20~36 VDC | G | ||||||||||

| 85~265 VAC | E | |||||||||||

| 9~36 VDC solar power | SD | |||||||||||

| Others | X | |||||||||||

Signal Output / Communication | 4~20 mA + Pulse + RS485 MODBUS | A | ||||||||||

| 4~20 mA + HART | B | |||||||||||

| 4~20 mA + Profibus PA/DP | C | |||||||||||

| GPRS | D | |||||||||||

Flange Process Connection | DIN D10: PN10, D16: PN16, D25: PN25, D40: PN40 | D** | ||||||||||

| ANSI A15: 150#, A30: 300#, A60: 600# | A** | |||||||||||

| JIS J10: 10K, J20: 20K, J30: 30K | J** | |||||||||||

| Others | O | |||||||||||

| Protection Grade | IP65 Transmitter + IP65 sensor | 1 | ||||||||||

| IP65 Transmitter + IP68 sensor (remote) | 2 | |||||||||||

| Transmitter | Square | A | ||||||||||

| Round | B | |||||||||||